Category: used construction machines、 Recycling Equipment、 excavator、 GRINDER、 screen、 soil-recycling、 wheel loader、 road equpment、 aerial platform、 demolition、 auction、 export、 dozer、 crusher、 forestry

Chukyo Juki Official Blog

2020 02.26

Category: used construction machines、 Recycling Equipment、 excavator、 GRINDER、 screen、 soil-recycling、 wheel loader、 road equpment、 aerial platform、 demolition、 auction、 export、 dozer、 crusher、 forestry

It is difficult to crush big rocks and concrete debris to the desired size at once. For this reason, we perform primary crushing to crush large chunks into small pieces, secondary crushing to make the primary crushed pieces finer or to adjust the grain size, The most commonly used primary crushing machine is a stone crushing machine called "jaw crusher". A jaw crusher can crush large rocks very efficiently, but it is not suitable to crush evenly. We deal with many used jaw crushers.

In the secondary crushing, the crushed material is hit against the wall to remove the corners to make the grain size uniform. At this stage impact crushers and cone crushers are used. In addition, there is a type called "roll crusher" which is a type of stone crusher that crushes while being rolled by a shaft. Roll crushers are only suitable to crush soft materials such as asphalt concrete.

Jaw crushers, which are representative of stone crushers, have been produced in Japan as self-propelled machines since the 1990s, and are relatively new. Before then, stationary stone crushers were used.

Demolition sites move frequently, and the cost for transporting a large amount of concrete debris is expensive. The cost can be reduced by crushing at the site of demolition rather than carrying out the crushed material once and transporting it back to the site.

Even if it is a quarrying site, if a quarrying site for shaving a mountain moves, it is necessary to carry rocks for crushing. Even at these sites, if the crusher could be moved, the work efficiency would increase, and the needs of the site increased. The self-propelled jaw crusher was born in Japan with the support of the recycling law which was enforced in 1991.

Including BR200 manufactured by Komatsu Construction Machinery, Mobile jaw crushers at very first were combined of undercarriage with stationary crushers. KOMATSU had manufactured and sale their original mobile jaw crushers independently with their know-how and also had been as one of the most major manufacture. KOMATSU named that “GALAPAGOS”. BR380JG is representative.

In fact, around 1987, we received many comments from customers in the demolition industry who said, "I want to crush concrete debris on site." For this reason, the original self-propelled jaw crusher was manufactured earlier than the Japanese domestic manufacturers by installing a jaw crusher and a generator made by Sato Tekko into the body of undercarriage made by Hitachi Construction Machinery.

Self-propelled jaw crushers made by domestic manufacturers have been moving independently since the early days.

In the 2000s, Caterpillar Mitsubishi sold mobile jaw crushers such as the MC 230 and MC 220, but stopped production and now imports and sells jaw crushers made in Europe (Sandvik).

Since around 2000, Hitachi Construction Machinery has shifted its import direction to the self-propelled jaw crusher LT series (LT 80, LT 105, LT 125) made by the European company Nordberg. After that, they sold the ZR Series (ZR 950 JC), which features a body of undercarriage made by Hitachi with a Nordberg (Metso) jaw crusher.

The self-propelled jaw crusher of Komatsu, which has a large share in the Japanese market, is a machine that is easy to use and has a high quality, but it is a little smaller than the one made in Europe.

On the other hand European self-propelled jaw crushers, on the other hand, are more large and powerful.

Jaw crushers made in Japan are generally designed for recycling, while those made in Europe are designed to crush stones calculated from crushed stone. Therefore, it can be roughly divided into two types, one made in Japan is suitable for crushing concrete debris and the other made in Europe is suitable for crushing natural stones.

Mobile jaw crushers mash rocks with great force, so it is easy to damage the machine by itself. Even so, if you manage the parts that are easy to wear and check the proper condition, you can repair it before it is too late.

The parts that are most likely to be worn and damaged are the moving jaw and the fixed jaw for grinding stone. These materials are made of manganese steel with high impact and wear resistance so that hard stone materials can be ground. However, as the stone materials are ground, they gradually wear out.

The cheek plate which constitutes the crushing chamber together with the moving and fixed jaws is also a part which is easy to wear and damage. The cheek plate is not a component for grinding stone, but it is made of wear-resistant steel because it surrounds the crushing chamber and supports the crushed stone.

The inside of the crushing chamber of the core where stone is crushed is also easy to wear, and the work efficiency lowers as the wear progresses. It is necessary to check the wear residue on a daily basis and replace the top and bottom of the jaws or replace them with new parts as necessary.

The moving line from the hopper into which stone application is injected to the crushing chamber is also a part that is easy to wear. The hopper is worn out, but it is a part where there are many dents and distortions due to impact when putting in the stone. Since materials with such high impact resistance are not used, reinforcement and repair to prevent dent distortion are necessary.

By vibrating the stone, the grizzly removes small stones while running a certain amount, but in the process wear out. In the case of severe wear, the grizzly bars break and the gap widens.

The stone that flows over the grizzly flows down into the crushing room, and a protector is attached to drop the stone into the crushing room. Protectors are very easy to wear because they are hit by fallen stone. The wear resistance value of the material of the protector is not so high, so there is a possibility that it is worn more than you think. Also, both sides of the protector are easy to wear, so you need to be careful.

The bearings (bearing cover) used to move the moving jaw are located on the back of the protector, and fine stones may enter through the gaps in the worn protector and damage the bearing cover. The protector is very easy to wear, so you have to replace it as soon as possible without leaving the wear.

It's hard to find the wear in the invisible part.

Visible parts, such as jaws and cheek plates, are easy to check for wear, making it relatively easy to replace or repair parts. However, if the wear on the back side is so severe that it needs to be repaired, it may be necessary to disassemble the product and repair it at a high cost.

For bearings and bearing covers, small stones may enter the space between worn protectors, resulting in wear of the bearing cover and possibly affecting the bearing. Worn bearings make smooth movement impossible and reduce work efficiency.

There is a mechanism to move the jaws behind the jaws. An eccentric pulley moves the moving tooth back and forth, and its fixed link connects the moving tooth and the eccentric pulley.

Rigid links with articular-shaped shapes can wear out over long periods of time. Since a large force is transmitted to the moving jaws, the deterioration of the operation due to the wear of the link leads to the lowering of work efficiency. In the worst case, the moving jaws don’t work anymore .

If the jaw crusher makes an unusual sound when operating, it is necessary to suspect a malfunction of the mechanism to move the jaw crusher on the back side such as a link. We recommend early detection and repair.

Self-propelled jaw crushers are, in a sense, a mass of wear, so there is a possibility of wear on every part. If you know what kind of parts wear fast, you can repair or change parts before the wear becomes serious. Also, when choosing a used jaw crusher, it is an important check point to see the degree of wear of the parts.

How to use of a self-propelled jaw crusher

A self-propelled jaw crusher is a heavy machine that has a large impact or vibration on itself during operation. Therefore, it is easy to wear out all parts of the machine, and overloading can lead to failure.

Therefore, in order to extend the life of a self-propelled jaw crusher, the key point is to handle it so that unnecessary load is not applied. I want you to pay attention to the size of the stone you put. The processing capacity varies depending on the specification and manufacturer of the self-propelled jaw crusher. However, even if you throw in an oversized lump, it will not be able to break it to the desired size, and it will be a big burden on the heavy machinery, which will cause a breakdown. It is necessary to check the processing capacity of your self-propelled jaw crusher, such as how much stone material can be crushed to the desired size.

You need to be careful not to put too much stone. All at once if too much stone is thrown into the crushing room, the work efficiency decreases and the burden on heavy machinery increases.

In the worst-case scenario, the crushing room may be damaged, so it is important to adjust the amount of charge so that the crushing room is not filled up. Although some relatively new types of self-propelled jaw crushers have sensors that detect the amount of stone in the crushing chamber, the most important thing is to stop the machine "Always" when you check inside the crushing chamber.

When concrete is crushed at a demolition site, reinforcing bars are inevitably mixed in it. If too long rebar remains, it may become entangled in grizzly, get caught in the crushing room, or tie the discharge belt. Remove long rebar that can be visually confirmed before crushing. Also, you have to be careful about the trouble that the claws of the hydraulic excavator come off and get mixed into the crushed material. When stone with high water content is crushed, soil or sand may adhere to the groove of the crushed tooth and bury it. When the grooves are filled, the crushing efficiency decreases, so it is necessary to avoid crushing in rainy weather and to crush after drying the stone.

In any case, pretreatment before crushing is the key to keeping the jaw crusher in use for a long time. It may seem a little troublesome, but it helps improve crushing efficiency, product accuracy, and prevent failures.

Maintenance method of the self-propelled jaw crusher

First of all, I want you to wash and clean frequently. Especially, please make sure to remove sand and soil which are stuck or not attached in the groove of broken jaws. Especially for machines that are in operation at demolition sites, alkaline concrete can corrode the coating of electrical wiring, and cleaning is important to prevent malfunction of electrical circuits due to disconnection.

Also, by doing the grease up firmly, the abrasion progress due to aging can be slowed down. In particular, wear around bearings and links leads to poor movement and poor crushing efficiency, which can lead to high repair costs. Please do the grease up every day to keep moving smoothly.

Please check the degree of wear by daily inspection. A self-propelled jaw crusher is a heavy machine that is easy to wear, so depending on the condition of wear, you should take measures as soon as possible, such as reversing the top and bottom of a broken tooth or replacing a protector.

hen you buy a used self-propelled jaw crusher, please make sure to check the wear condition of the input hopper, grizzly bar and protector.

If the input hopper is reinforced, make sure it is reinforced with wear resistant steel. If it is reinforced with a regular iron plate, it may wear out soon.

Next, check the wear condition of the crushing room. If the cheek plate is worn out, the lower part will get shaky. Especially the lower part is hard to see, so please check it carefully. Also, it is the point to check the jaws whether can be still useful or not in reverse.

Check the condition of the bearings and bearing bars around the protector. Even if the protector is not worn, parts such as the bearing cover may be worn. Also check that the belt attached to the eccentric pulley for moving the jaws is not cracked.

And in the case of the lock cylinder type, please check the oil leakage from the cylinder and whether the gap can be adjusted properly by actually moving it. If you do not remove the cover, you will not be able to check the area around the lock cylinder, but you can remove it easily by removing only a few bolts. Chukyo juki always makes effort to maintenance our machines even small things like removing bolts. The reason why so many customers choose us.

Move the self-propelled jaw crusher and then check the rattling of the link. Normally, you can hear beautiful mechanical and rotational sounds, but when the rattling occurs due to the wear of the link, you will hear a strange noise such as "Clang Clang".

Self-propelled jaw crushers require daily grease, so grease tubes are placed around the area where the grease is applied. Let's check if the grease tube is connected properly by tracing the tube. You can check the grease tube by raising the rubber parts on both sides and looking into it from below.

In addition, the unloading belt conveyor may be damaged by the mixed reinforcing steel, etc., so rotate the belt conveyor slowly and check for cracks, chips, or traces of repair due to damage, etc.

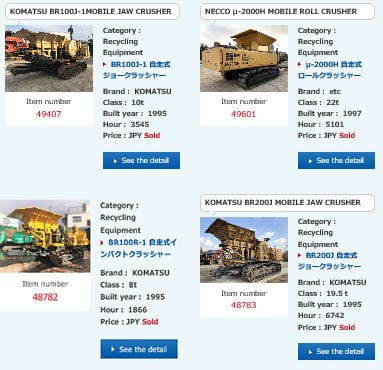

Click here to see the inventory of recycling equipments.↓

Rock crushers include jaw crushers, impact crushers, cone crushers, etc.

What is important in maintenance mobile crusher is cleaning, grease up and checking the degree of wear.

When you buy a jaw crusher,you ha better to buy from a construction machine dealer who knows well about crushers.

MARUMORI-KUN