Category: used construction machines、 Recycling Equipment、 excavator、 GRINDER、 screen、 soil-recycling、 wheel loader、 road equpment、 aerial platform、 demolition、 auction、 export、 dozer、 crusher、 forestry

Chukyo Juki Official Blog

2020 02.25

Category: used construction machines、 Recycling Equipment、 excavator、 GRINDER、 screen、 soil-recycling、 wheel loader、 road equpment、 aerial platform、 demolition、 auction、 export、 dozer、 crusher、 forestry

There are two main types of self-propelled wood crusher: 'tub' and 'horizontal'. The selection of these types of crusher has a significant impact on the efficiency of the crushing operation.

Mobile tub wood grinder suitable for crushing large amounts of thick (large) wood or roots

The mobile tub wood grinder is a type of crusher that crushes wood thrown into a round bowl-shaped Tub (hopper). In addition to wood, it is also good at crushing the trunk of curved broad-leaved trees and their roots, as well as the trunk close to the root, because it is inserted from the open tub.

When using a tub-type wood grinder, attention should be paid to the following: depending on the size of the wood to be added, it should be crushed into small pieces before being thrown into the crusher. To crush straight wood longer than its diameter, it should be cut into pieces about 2 meters long in advance. In addition, since the wood put into the tub comes into contact with the crusher at the bottom due to its own weight, when its own weight decreases, the crusher turns idle, and as a result, only about 80% of the material put into the tub can be crushed.

Horizontal grinder suitable for crushing small amounts of wood and long strips

A horizontal type wood crusher is a mechanism in which wood is put into a hopper conveyor, and a compression roller roller grinds and crushes the wood while feeding it. Therefore, even a small amount of wood such as just one can be crushed firmly. Also, it can crush long and thin waste materials without cutting. However, lumber larger than the height of the entrance of the crushing room (≈ the thickness of the wood) cannot be sent, so there is a limit to the thickness of the shredder. Another characteristic of bamboo is that it tends to produce streaky fibers. When broken into pieces using the tub grinder, the fibers accumulate in the space between the tubs, causing the hopper to break down. Therefore, we recommend a horizontal wood crusher for crushing bamboo.

In summary, the theory is that the tub grinder is used to crush stumps and roots, and the horizontal grinder is used to crush waste wood that has be dismantled and elongated wood.

Japanese machine VS non-Japanese, depend on the anount to be crushed.

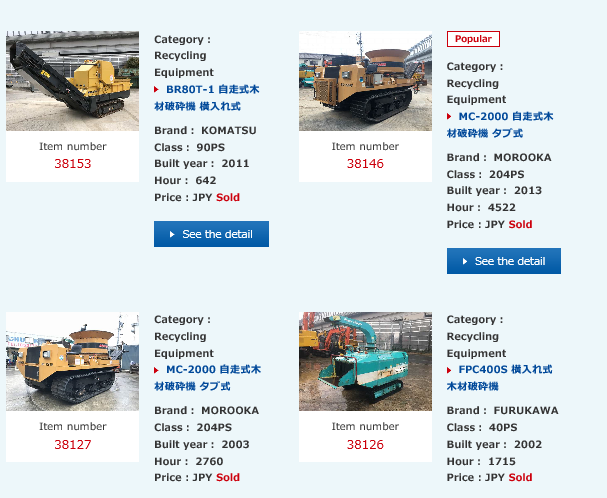

Komatsu, Morooka, Hitachi and Furukawa are among the Japanese manufacturers of self-propelled wood crushers. There are also manufacturers in the United States and other countries that are home to wood crushers. Typical examples include Peterson, Mobark, Doppstadt, Jenz, Willibald, and Forus.

The wood crusher made in the United States, such as Vermeer and Mobark, which is considered to be the center of the wood crusher, has a simple design using a direct clutch. In Scandinavia, where forestry is flourishing, crushers made by Zenoah of which structures are elaborate and the control is complicated. Made in Germany and Italy have similar feature. By the way, there are manufacturers of dual shafts grinders and single shaft grinders in Germany such as Forus Hammel.

Japanese and non-Japanese manufacturers tend to be as follows.

* Japanese

Size: Small/Medium Engine power: 100 ~ 300 ps mainly

* non-Japanese manufacturers

Size: Mainly large Engine power: More than 400 ~ 700 ps

In Japan, It is in high demand that small and medium-sized self-propelled wood crushers, considering the the limited space, convenient mobility on Job site and the amount of chippers required in Japan. On the other hand, if a large amount of chippers is required that cannot be achieved with small and medium-sized wood crushers, it would be better to choose a non-Japanese manufacturer.

Outside of Japan, self-propelled wood crushers are used for the production of chips, waste treatment, and compost-fiber for forestry management. In terms of the characteristics of each country, in Southeast Asia, such as Thailand, where there are almost buildings used by wooden materials, demolition of houses and crushing of waste materials were the main applications. In Taiwan, where typhoons frequently strike, these materials are used to dispose of disaster waste.

Breakage of the crushing chamber due to contamination with foreign matter

A self-propelled wood crusher has mechanism to crush wood by striking it against a crushing bit or an anvil plate with enormous force. Therefore, foreign substances other than those subject to crushing, such as stone and iron, may enter the crushing chamber and damage the structure inside the crushing chamber . Most wood crushers are equipped with magnetic separators and are designed so that iron as large as nails can be mixed in. However, there is a risk that metal parts such as bolts and nails in waste materials will be mixed in waste materials, especially in the case of crushing operations at demolition sites. Depending on the size of the foreign matter, the cutter drum or crushing bit may be damaged. Therefore, it is important to remove the foreign matter before feeding it in the machine, and to stop the operation immediately if a strange noise is heard during the crushing operation.

System error due to electrical system trouble

Many of the self-propelled wood crushers are equipped with electronic control of safety devices and operation methods to prevent accidents, and many electronic circuits. If wood chips produced by wood crushing are accumulated inside a wood crusher and left untouched, the accumulated wood chips will decompose over time, spoiling the covering of electrical wiring and causing disconnection If there is no reaction after starting the machine, there is no defective part in the wood crusher body, but the above trouble is occurring in the safety device or electrical system. There are many cases in which an error call is displayed on the display, causing the wood crusher to fail to start.

Fire caused by a wood grinder

Unfortunately, a lot of fires have occurred at woodchip production sites where self-propelled wood crushers are used. For example, it is spontaneous ignition. The inside of the accumulated wood chips ferments, and the heat leads to spontaneous ignition. For example, when leaf litter is turned into leaf mold by fermentation, the inside temperature rises up to 70 ° C due to the heat of fermentation. The slope becomes steeper when the crushed chips are loaded directly from a self-propelled wood crusher into a dump truck by setting the slope of the discharge belt. Wood chips may accumulate at the base of the unloading conveyor, leading to spontaneous ignition. Other than that, when metal is mixed into wood, it may collide with the drum in the crushing chamber and produce sparks. Sparks fall on wood chips and cause a fire. Fires are rarely used at the site of wood crushing, but in the case of self-propelled wood crushers, which often use diesel engines or hydraulic motors, the cutter rotor and other parts of the heavy machinery themselves or the frictional heat generated during crushing heats up. If wood chips accumulate in the gap of them, it often leads to a fire.

Users need to be very careful about fire because they are handling large quantities of flammable wood. If there are many accumulated chips, there may be no sign on the surface, but combustible gas may be generated inside by fermentation. The gas leads to spontaneous ignition. When wood chips are piled up and left as they are, the rainwater that seeps into them promotes fermentation, so that the accumulated wood chips should be leveled out and the amount should be reduced to eliminate the risk of fire.

It is also important to ensure that the pre-shredding process, such as sorting the shredded material, is carried out properly, and to stop the work immediately if abnormal noise is detected during the shredding process to check the condition of the shredder.

We , Chukyo-Juki, bear daily cleaning in mind the solution of the common troubles isalso cleaning the machine . At the end of each day, the opening and closing of the tub and the hatch of the chamber must be opened, and wood chips must be removed with an air compressor or blower. Most of the heat exchangers such as oil coolers of mobile wood crushers around the air intakes of engines are dust-proof. However, when wood is shredded, a large amount of wood chips, sawdust, and wood flour are scattered, and if cleaning is insufficient, cores and filters may become clogged, reducing dust-proof functions. An engine with a reduced cooling function or a power train that uses a lot of oil pressure will suddenly lose its performance and overheat. It is necessary to implement measures to prevent accidents by incorporating cleaning after the shredding operation and inspection time during the operation into the work plan.

Bearings that are difficult to determine timing to replace

Bearings are easy to wear, but it is difficult to notice because there is no indication of replacement. Therefore, it may cause rattling or abnormal noise if you continue to use it without paying much attention. Absence of abnormal noise is one of the checkpoints when choosing a used wood crusher.

Consumption time that varies with bit structure

The consumption time differs depending on the type of bit to grind. In the case of the hammer bit type used to produce the commonly used pin chips the crushing efficiency decreases in about 100 ~ 200 hours depending on the material to be crushed, requiring replacement. On the other hand, cutter type bit used to produce cut chips recommended to be replaced in about 8 hours, depending on the manufacturer.

There is a self-propelled wood crusher that can produce cut chips from the demand in biomass power plants. However, the cutter has to cut off the fibers of the wood and make the cross-section linear (so that they don't form an arch when they're fed into the incinerator.), which increases the burden on the bit edge. You can make it last longer by replacing it regularly before it breaks.

Efforts to reduce maintenance costs for wood crushers

For hammer bits, it is ideal to use genuine parts whose crushing efficiency is guaranteed in the throughput calculation. However, it is effective to use imitation parts that are low in cost and to try to use them in terms of cost reduction.

Review cutters

In order to reduce costs, it is necessary to consider whether to use a disposable type, which is inexpensive, or a re-polishing type, which is expensive. In both cases, it is important to consider the number of cutting blades and maintainability of the wood crusher to be used, and to consider the cycle of reuse of spare blades. For parts that cannot be easily replaced, such as the crushing rotor, it is also effective to reinforce the parts that are easy to wear by welding flat bar steel. In addition, it is useful to balance the crushing rotor after reinforcement. Using the same principle as that of automobile tires, balancing reduces vibration during crushing and prevents cracks in the frame. I'm sure you can expect fuel efficiency. The grease to the bearing holding the crushing rotor should be frequent. The crusher rotor of the wood crusher is characterized by high speed rotation, so I think it is quite hot. When the rolling element causes flaking, a "GO" sound is produced, causing rattling. When the rolling element causes galling, a "CLANG" sound is produced. It needs to be replaced, but even if you match the standard dimensions with the general purpose bearing catalog, it is better to use a genuine part. It is important not only to reinforce but also to maintain the shaft.

In the case of a wood grinder made in Japan, the steel plate is about 9mm thick, so it is relatively easy to make your own screen. The hole diameter can be set to match the size of the wood chips produced. When a laser beam machine is used, an ordinary steel iron plate with a thickness of 9 ~ 11 mm can be cut, so we can reduce the cost of purchasing a new screen by taking measurements of the desired screen and asking a boiler processing specialist to manufacture it.

However, it seems to be difficult to make a non-Japanese wood crusher by yourself because the iron plate of the screen is thick.

The tub grinder is used to crush stumps and roots, and the horizontal grinder is used to crush waste wood that has be dismantled and elongated wood.

Daily cleaning is really important.

MARUMORI-KUN